5 Heavy Equipment Maintenance Tips

Written by Marilee Brewer

January 26, 2023

Heavy equipment is the most expensive construction equipment you'll own. That's why maintaining your equipment is just as important as purchasing the machines in the first place. It's estimated that 82% of construction businesses have four hours or more of unexpected downtime each year, with costs that can reach into the millions.1

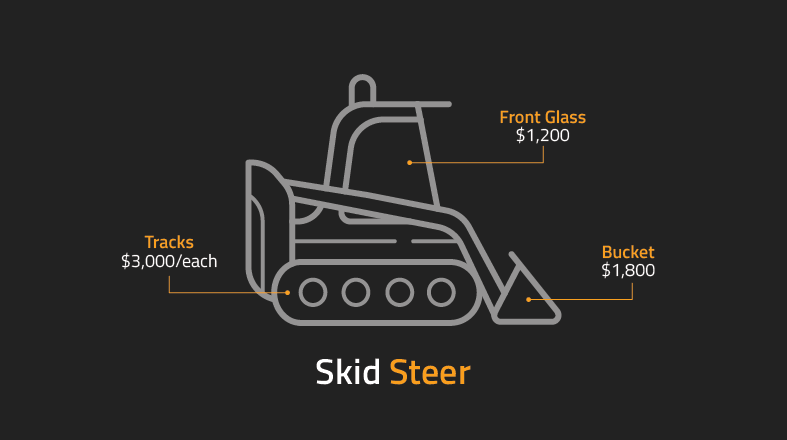

Even if you're just replacing parts, things can add up quickly. Take a look at the average cost of skid steer parts according to one of BuildWitt's leaders and construction veteran Jay Collup. With thousands of dollars for small parts, $150+ per hour for labor, and the staggering cost of your own downtime, even minor mechanical breakdowns can quickly put you in a pickle.

These machines aren't simple, they're complex mechanical behemoths. Even the newest, top-of-the-line excavator is subject to problems that stem from neglect. Pins can prematurely wear or seize. Engines can lock up or blow up if they're not serviced according to the manual. The vast majority of breakdowns can be directly attributed to a lack of care.​

Don't let ignorance cost you downtime. Use these five tips to help lengthen the life of your big machines and give you a competitive edge:

1. Know your machine

2. Establish a routine maintenance plan

3. Document all maintenance procedures

4. Keep 'em clean

5. Train, train, train

1. Know your machine

Saving thousands of dollars in repairs starts with knowing your equipment inside and out, whether that's the excavator, dozer, or skid steer that you run. Fortunately, you don't have to go on a wild goose chase to find out the details—everything you need to begin is documented in the owner's manual.

Setting aside time to read and understand the equipment manual should be required for all those who touch your fleet. Every manual tells you recommended service times for each part of the machine, advice on what products to use, and a description of acceptable operating conditions.

Basic malfunctions can also be resolved by referring to the owner's manual. The owner's manual includes troubleshooting information and instructions on what to do when the equipment malfunctions.

2. Establish a routine maintenance plan

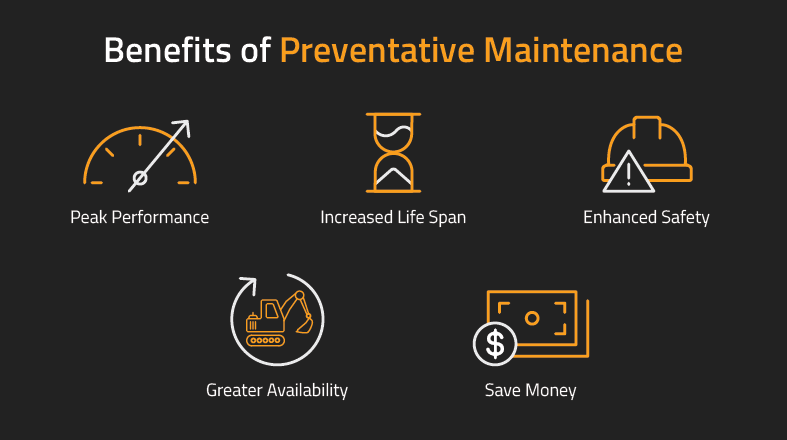

Preventative maintenance can reduce repair costs by 25%.2 So it's important to have a plan—especially if you're in a line of work that's extra hard on equipment, like ag development. You should commit to a program of care when you acquire a new piece of heavy equipment. A program will help you anticipate normal wear and track changes in your machine.

A good preventative maintenance plan includes regular inspections, swapping parts, and testing. These days, most machines can get monitoring systems that enable you to track their performance remotely. Use that information to create a complete picture of what each machine needs.

The benefits of routine maintenance go beyond extending the life of your machinery. They can also save you money, increase performance, enhance safety on the job, and create greater availability, allowing you to bid on bigger jobs.

3. Document all maintenance procedures

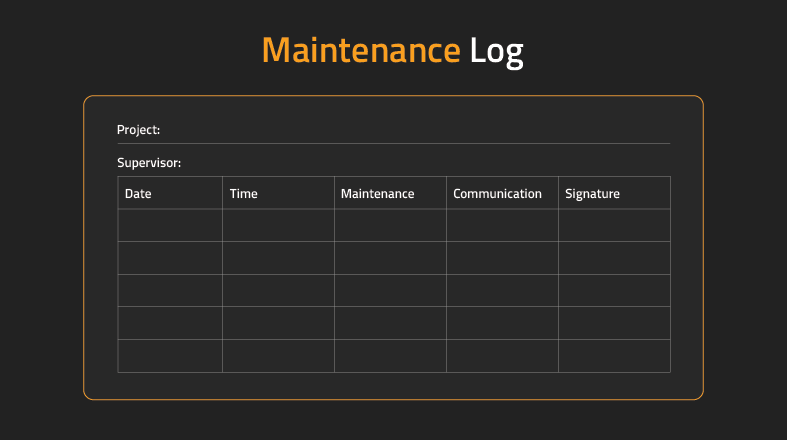

If you're in construction, you're no stranger to record-keeping. Detailed machine maintenance records will give you the info to maintain your fleet properly. Recording all communications and notes around machine maintenance will allow you to communicate vital information to the mechanic. It will save you time and money and ensure that each piece of equipment gets the proper treatment.

Keep your maintenance log in a visible place

Posting a maintenance log in a visible place, cover it with plexiglass, and attach a grease pencil to a string near the maintenance record. The chart should indicate the time, the maintenance performed, and the person checking the equipment. Require each shift to fill out a line on the maintenance log and record any comments about the machine's performance.

In addition to the maintenance log, keep a small notepad and pencil in every piece of equipment so operators can jot down notes related to the machine's performance while operating in the field.

While maintenance logs can get as detailed as you want them to be, each log should have the following basic information:

- Project name

- Project manager/field supervisor

- Date

- Time

- Problems/comments

- Maintenance performed

- Name/signature

Lube it or lose it

Checking lubricants may seem like a no-brainer, but it's one of the biggest reasons equipment freezes up mid-stroke. Lubricants reduce friction between moving parts, slowing the normal wear and tear on the engine, pumps, and wear points. By monitoring lubricant levels, you can make a difference in the lifespan of your machine.

Every owner's manual will have directions for replacing lubricants, and you must follow these instructions. Deviating from the recommended amounts can damage your machine and reduce its life span. Be sure to use the recommended lubricant according to each manufacturer's specifications.

4. Keep 'em clean

Dirty equipment is a hazard to operators and to the equipment itself. Caked-on dirt and grime can cause your machine to overheat and wear down much faster than usual, and mud can obscure damage like cracks and scratches that need attention before they get out of hand.

Build machine cleaning into the regular schedule. Use high-pressure hoses to remove dirt and debris from hard-to-reach areas, like treads and wheels. Follow the manufacturer's specifications when it comes to frequency and manner of cleaning.

5. Train, train, train

The single most important factor in machine life is training your people to care for, understand, and operate machinery within specified limits. If you train your operators to care for the equipment, you can make caring for your heavy equipment something that the whole team is engaged in. Operators spend most of their day in the machine, so if you're not leveraging their relationship to the equipment, you're missing out on a huge opportunity.

In-house training

Offering training to your technicians and your operators can lengthen your machine's life and improve the crew's overall productivity. Providing your staff with in-house training enables them to stay on top of new technologies and changes in procedure. It's one thing to know how to operate a skid steer and another to care for the equipment from start to finish.

In-house training should always include demonstrations of how to use your equipment and the functional parameters for each piece of machinery. Misusing or mishandling heavy equipment is another big cause of breakdowns, so training your people well can minimize the chance of accidents that result in machine damage, lowering your repair bills and lengthening the life of your equipment.

Daily checks

As a part of their training, employees should learn to perform a series of tasks from a daily checklist. Do these at the beginning or end of the day. Regular quick checks can identify mechanical issues and allow you to resolve them before they become bigger problems.

A minimum daily checklist should include the following:

- Brakes and brake fluid

- Hydraulic fluid

- Transmission fluid

- Tire pressure

- Gauges

- Horn

- Lights

- Reverse Alarm

- Seat Belts

Keep each day's checklist with the maintenance logs, and at the end of the day, take a few moments to review them. Store the notes for each vehicle in that vehicle's document folder. Keeping a working history of each machine will give your mechanic an advantage in the repair and upkeep of your fleet.

Try BuildWitt Training

Statistics tell us that 62% of equipment breakdowns are due to lack of maintenance, with a whopping two-thirds of all heavy equipment insurance claims paid on account of lack of care.3

By training your operators well, you can engage them in the overall care and preventative maintenance of your machines. With BuildWitt Training, they will learn how to perform daily checks, fill out a maintenance log, take notes on the condition of the machines they are operating, and prepare their equipment for work. As a result, you'll save tens of thousands of dollars and increase the lifespan of your heavy equipment.

Besides, we make it fun and relevant to construction. Operators can learn from true industry veterans in a real setting, with micro-lessons aimed at communicating snippets of information that can immediately be put into action.

Want to see for yourself? Check out BuildWitt Training's Operator Course today.

More about

Sand Cone Test for In-Place Density Testing Soil by Sieve - Minus #40 How to Determine Moisture Content in SoilMeet the Expert

Marilee Brewer

Marilee Brewer's philosophy on heavy civil construction is that everything—even the Bingham Canyon Mine and the Willis Tower—starts with ideas put into words. An avid writer and researcher, Marilee brings inspiration, storytelling, and human candor to Dirt World information. Her writing focuses on providing content that enhances user experience, improves engagement, and ultimately increases revenue. A trained Linguist and social media storyteller, ask her for story and social media writing tips.